|

Anyang Xinheng Machine Tool Co.,Ltd.

|

Automatic control bearing ring manufacturing machines

| Price: | 155000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

XSPT-002 bearing ring automatic line with three ADJ15P CNC lathes and a set of SMT20 Manipulator automatic loading and unloading device.

AUTOMATIC BEARING RING PRODUCTION LINE:

XSPT-002 bearing ring automatic line is composed of three ADJ15P CNC lathes and a set of SMT20 Manipulator automatic feeding device.

The automatic line to grab the workpiece weight ≤ 7Kg.

Outer diameter: 100mm-200mm

The width of disk type parts: 14mm-70mm.

Designed according to user-specific requirements.

| Workpiece | Bearing out ring(No. CG-GAC110S/K.01-LG1) |

| Annual output estimation | 12 months×26 days×20 hours×3600 seconds×0.85 Utilization rate/85 seconds(Automatic line cycle time)= 224640 pieces. |

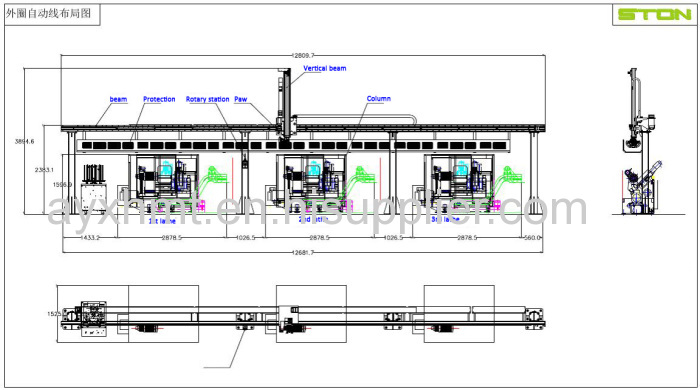

LAYOUT OF THE BEARING RING LATHES:

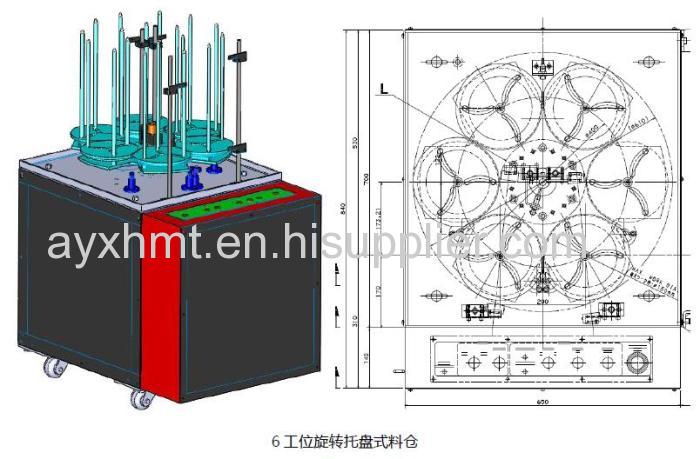

SIX-STATION ROTARY TRAY SILOS:

The feeding device of the automatic line is composed by the 6 Station pallet type rotary silos, and the silo is controlled by the sensor induction signal. It can control the feeding position and the stroke of each action.

Silo specifications: 6 stations.

Delivery parts diameter: Φ30 ~ Φ230;

Each station stack height: 400mm.

Each tray carry weight: 35kg.

APPLICATION:

BEARING RING TURNING:

FLANGE PARTS:

Related Search

Bearing Ring

Ring Bearing

Automatic Brick Making Machines

Automatic Coffee Machines

Fully Automatic Washing Machines

Automatic Assembly Machines

More>>

.jpg)

.jpg)